AP Services

Style 6500

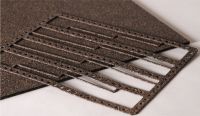

Style 6500 Hochdruck is a multilayer high strength sheet material using .020” thick layers of high quality graphite foil and .002” thick 316 stainless steel foil. Depending on the sheet thickness required, several layers of graphite and stainless steel foil are joined together using a unique binding process. These layers are fused together without the use of glues or adhesives that can burn out or delaminate at elevated temperatures. This material has a very high compressive strength, high bursting safety and high rigidity.

Style 6500 has outstanding durability and excellent sealing capabilities in high temperature and pressure applications. It can easily be fabricated with normal gasket cutting tools.

Style 6500 is available in sheets and pre-cut gaskets.

| Temperature Range | -400 ºF to 850 ºF oxidizing atmospheres |

| Pressure | 2,000 psi maximum |

Style 6300R

Style 6300R is a graphite sheet manufactured from 97% pure graphite flakes with a .002” thick stainless steel sheet laminated between the flexible graphite layers. The result is a mechanically stronger sheet with better handling characteristics, processed without resins, binders, or other additives that would limit corrosion resistance and high-temperature applications. Style 6300R is permanently resilient, non-hardening, naturally lubricious, and has an infinite shelf life. Flexible graphite has the seal of approval by companies handling corrosive, volatile, or flammable media.

Style 6300R is an ideal sealing material for high-temperature applications. It is also resistant to attack by most molten metals, corrosive chemicals, and caustics. Style 6300R is still an easy material to fabricate even with the Stainless Steel laminate.

|

Style 6300R is available in sheets and pre-cut gaskets

|

|

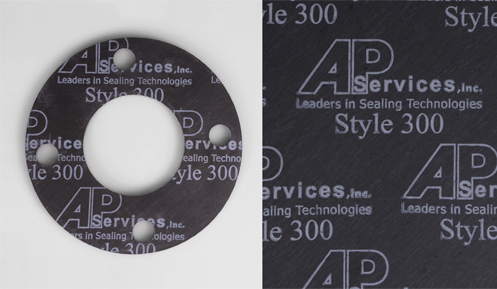

Style 300

Style 300 is a high quality, compressed fiber sheet designed for extreme service. Carbon and graphite fibers combined with a heat-resistant, nitrile binder allow for high temperature service.

Style 300 can be used for sealing water, steam, fuels, lubricants, alkalis, and weak acids, seeing maximum temperatures to 800º F and maximum pressures to 1450 PSI. Continuous operating temperature 552 ºF.

The Pressure x Temperature Factor for Style 300 1/16” is 600,000 max.

Style 300 is available in sheets and pre-cut gaskets

Style 325

Style 325 is a high quality sheet composed of non-asbestos synthetic fibers and a heat resistant nitrile rubber binder. This non-asbestos sheet has low chloride content (below 100 ppm) and has good anti-stick properties, preventing flange corrosion and reducing maintenance time.

Style 325 can be used for sealing gases, water, organic acids, alkalis, and a wide range of applications seeing maximum temperatures to 500 ºF and maximum pressures to 1450 PSI. Continuous operating temperature 375 ºF. The Pressure x Temperature Factor for Style 325 1/16” is 350,000 max.

Style 325 is available in sheets and pre-cut gaskets.

Style 330

Style 330 is a high quality commercial grade compressed fiber sheet designed for a wide range of services. Synthetic, non-asbestos fibers combined with a modified, heat-resistant SBR binder allow for high temperature service. Style 330 has enhanced controlled swell properties that create a tight seal when exposed to fluids and liquids, making an excellent sheet for low bolt load applications. This sheet provides great flexibility, good shelf aging resistance, and long service life.

Style 330 is recommended for hot oil, gases, saturated steam, ammonia and applications under 500 ºF and pressures to 1450 PSI. Continuous operating temperature is 375 ºF.

The Pressure x Temperature Factor for Style 330 1/16” is

350,000 max.

Style 330 is available in sheets and pre-cut gaskets.

Thermiculite® 815

Thermiculite® 815 is a high temperature sealing material based on a blend of thermally and chemically exfoliated vermiculite. It offers benefits compared to both graphite and mica based sheet sealing materials. As a silicate based mineral vermiculite is free from the oxidation problems suffered by graphite in elevated temperature service in the presence of atmospheric or product stream oxygen. Unlike mica based sealing materials proprietary processing results in exfoliation of the vermiculite crystals producing a gas tight structure. The re-structured vermiculite is bonded to a 316 tanged stainless core enhancing handling characteristics and bow-out resistance.

Thermiculite 815 is primary designed for use in both standard and non-standard flanged connections in elevated temperature sealing applications where oxidation may be of concern. Typical applications and industries include incinerator combustion flues, mineral acid production, metal and ore processing, propulsion and genset exhaust systems, titanium dioxide production, steam and gas turbines.

The maximum temperature for Thermiculite 815 sheet is 1800°F (982°C). The maximum pressure is 2900 psig.

Thermiculite is available in sheet and pre-cut gaskets.

Style 720/730/724

Polytetrafluoroethylene (PTFE) is a thermoplastic member of the fluoropolymer family of plastics. PTFE has a low coefficient of friction, excellent insulating properties, and is chemically inert to most substances. It also can withstand high heat applications and it is well know for its anti-stick properties.

Style 720 Mechanical Grade PTFE- Manufactured from 100% reprocessed PTFE. Style 720 can handle virtually all chemicals in the 0-14 pH range with the exception of molten alkali metals and elemental fluorine. It is recommended for fuels, lubricants, caustics, and acids at temperatures up to 500°F. Style 720’s tensile strength is 1500 psi. Dielectric (Volts/Mil)- 1300.

Style 730 Virgin PTFE- Manufactured from 100% virgin PTFE. Style 720 can handle virtually all chemicals in the 0-14 pH range with the exception of molten alkali metals and elemental fluorine. It is recommended for fuels, lubricants, caustics, and acids at temperatures up to 500°F. Style 730’s tensile strength is 3000 psi. Dielectric (Volts/Mil)- 600

Style 724 Glass Filled PTFE- Manufactured from virgin PTFE and reinforced with glass fibers. With similar qualities as Style 720 and 730, Style 724 has as much as 40% higher compressive properties and improves wear resistance greatly due to the addition of glass. These compounds resist acids and oxidation, but can be attacked by alkali. It is recommended for fuels, lubricants, caustics, and acids at temperatures up to 500°F. Style 724’s tensile strength is 1000 psi.

Style 440

Style 440 is a combination of medium size cork particles and glue glycerin. It is an excellent medium compression composition cork that is fungus resistant. Cork works well on oils and gasoline, and is good for gaskets requiring low to medium torque loads such as fluid seals, gear boxes, oil seals, and valve covers.

Style 440 is available in sheets, bulk rolls (special order), and pre-cut gaskets.

Style 441

Style 441 is manufactured from a blend of fine cork particles and neoprene, forming a smooth and compressible sheet. It has high tensile and tear resistance, and low compression set. Style 441 will take medium bolting pressure, has excellent heat resistance, and moderate swelling in oils and fuels.

Cork & Neoprene sheet works well on oils, gasoline, Freon, and most solvents. Style 441 is good for gaskets requiring low to medium torque loads such as fluid seals, gear boxes, oil seals, and valve covers.

Style 441 is available in sheets, bulk rolls (special order), and pre-cut gaskets.

Style 444

Style 444 Oilrite is a superior grade of vegetable fiber sheet manufactured from a combination of plant fibers and chemical additive. Oilrite effectively resists the solvent action of petroleum products. It remains tough and durable through a long service life but is pliable and compressible for secure installation.

Style 444 is a resilient material for light bolt loading applications, and is recommended for oil, gasoline and most solvents.

Style 444 is available in sheets, bulk rolls, and pre-cut gaskets.

Standard thickness: .006”, .010”, 1/64”, .021”, 1/32”, 1/16”, 1/8”