OEM Gasket Reverse Engineering

How the Process Works

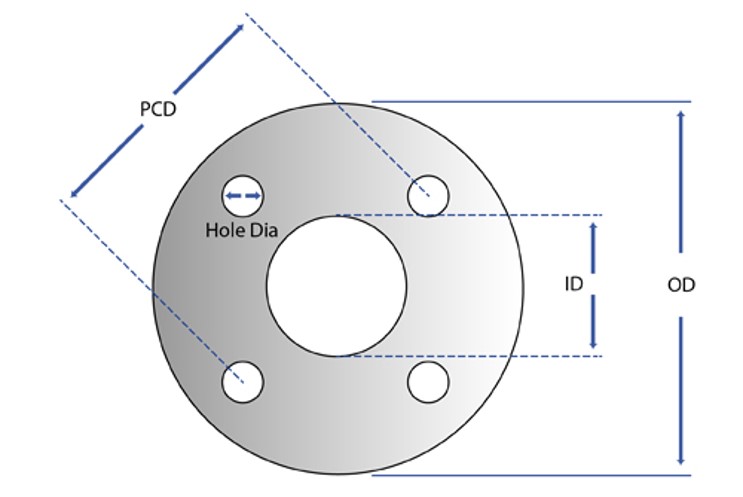

STEP 1: An OEM gasket is picked for

reverse engineering

STEP 2: Kan-Seal uses it’s state-of-the-art scanner to create an electronic replica

of the gasket.

STEP 3: Dimensional information, material type, and other pertinent information such as application pressures and temperatures are uploaded into our database for future reference.

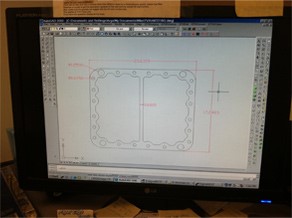

STEP 4: Using the 2D scan, a Kan-Seal technician creates a CAD Drawing to be

sent to our WaterJet cutter.

STEP 5: The CAD drawing is sent electronically for upload into the

WaterJet computer database.

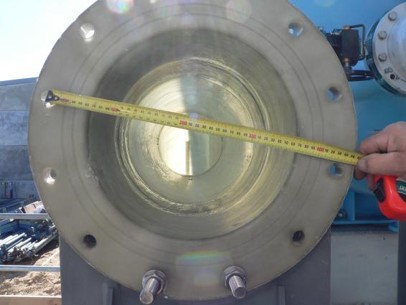

STEP 6: A dimensionally identical gasket

is created.